2000KN Computer Control Electro-Hydraulic Servo Universal Testing Machine

Applications:

Computer Control Servo Hydraulic Universal Testing machine is guaranteed to meet

ISO15579-2000, ISO679, ISO7438-1985, ISO6892, EN100021-1-2001, ASTM E8M, JIS Z2241-1998,

ISO75000-1, ISO4012, ISO10065 and other international and national specifications, which are suitable for tension, compression, bending, shear and other tests by adding different test fixture for metal and non-metal materials. It adopts hydraulic power pack to drive the piston in the oil cylinder to provide testing load. By using load cell and photoelectric encoder, the computer is timely showing the testing parameters like testing load, piston stroke, deformation of specimen and various kinds of testing curves etc. This machine is servo control mode and the computer with strong function software does data processing and issues the test reports. The software based on Windows system is able to make automatic calculating of test results, i.e. tensile strength; upper / lower yield strength, Non proportional stress point etc. Report creation function makes it is very simple to make testing report in needed format. It is necessary inspect device in the filed of steel and iron factory, the laboratories of scientific research institutes, infrastructure construction organs, machinery plants and education for research and teaching , etc.

Load frame:

Rigid four-column & two -lead screw construction & compact design

Dual workspace design: Upper for tension, Lower for compression or bending tests

Movable lower crosshead providing exceptional ease of operation

Accurate force measurement through precision load cell

With open front hydraulic wedge grips for easy change of inserts and specimen loading

Integrated displacement photoelectric encoder

Cylinder mounted at the bottom of the machine

Machine Features:

1. Load measurement: adopting load cell to ensure high accuracy, reliability and consistency;

Load meets or exceeds the following standards: ASTM E4, ISO75000-1, EN 10002-2, BS1610, DIN

51221.

2. Displacement measurement: adopts optical encoder with high accuracy and stability;

3. Strain measurement: Adopt high accuracy electronic extensometer: Strain measurement meets or

exceeds the following standards: ASTM E83, ISO 9513, EN 3846 and EN 1002-4.

4. Compact structure: with dual testing spaces and easy to adjust testing space to carry out different test

of varying-length specimens; The machine has four column and two screw with strong stiffness;

5. Clamp automatically: uses hydraulic grips with reliable holding;

6. Multi-protection: protection of over-load by software and hardware; position-limited protection of piston

and lower crosshead;

7. Test report can be acquired according to requirements of customers;

8. Management of test data: uses Access, Excel and other such kind software to communicate with

testing data base;

9. Stable performance with little influence of temperature and voltage;

10. Multiple Servo control mode : Load (Stress) Control; Displacement (Stroke) Control, Strain

(Deformation) Control. Load keeping, Displacement Keeping, Customized programming Control, etc

Safeguard:

Overload protection: When the testing load is over 2%-5% of Max. Load, the system will unload.

Stroke protection: When the ram arrives at the upper limited position, the motor of oil pump will stop

Control Unit:

1. Constant speed piston stroke control:

Control range: Ram stroke speed

Setting range:0.5~50mm/min

2. Constant speed load control: Control range:2~100%of full scale load

3. Displacement-keeping control

4. Load-keeping control

5. Constant speed strain control range: 5~100% of full scale strain

6. Emergency shut down button & over load protection (auto stop) function equipped and return to the specified position automatically.

7. Control mode of operation: Auto/Manual function changeable

8. Automatic endpoints: The tester stops automatically while specimen breaks

9. Display of testing parameters: Value and real-time curve (Load and Stroke), available to display and switch from computer. Also the elongation can be calculated.

Main technical specifications:

Max load: 2000KN

Load range: 20-2000kN

Load resolution: 1/200000

Load accuracy: ≤±1%

Deformation accuracy: ≤±1 %

Driving method: Hydraulic system

Test curves’ mode: Load – deformation, Load – time, Load-Displacement, Stress-Strain, Time-Stress,

Time-Strain, Deformation-Time, Displacement-Time, etc

Velocity display mode: loading velocity, strain velocity

Parameters processed with computer: Upper & lower yield point strength ReH & ReL, max. load point,

breaking strength, stress, deformation, elongation rate, elastic modulus & бP0.2.etc.

Control mode: Displacement control; Load control; Strain control; Stress Control.

Max. Tensile space: 750mm

Clamps for flat specimen: Thickness 0 – 40mm

Clamps for round specimen: Diameter Ø 12-60mm

Max. Effective Compression space: 600mm

Compression plate diameter: Ø 148mm

Max. Bending test effective space: 600mm

Ram stroke: 250mm

Crosshead lifting speed: 280mm/min

Testing Speed control range: 0.5-50mm/min

Load measuring mode: Load cell

Displacement measuring mode: Photoelectric encoder

Deformation measuring mode: Extensometer

Power supply: 380VAC, 50Hz, 3-Phase

Standard Accessories:

1. Grips for round specimen (Dia.) Φ12~Φ26mm, Φ26~Φ40mm, Φ40~Φ60mm 3 sets

Grips for flat specimen (thickness) 0~20mm, 20-40mm 2 sets

2. Bending attachment 1 set

3. Compression plate Dia. 148mm 1 set

4. Load cell 1 set

Flat load cell +/1000kN, Tensile & Compression type

5. Electronic extensometer 1 pc

Generally offer gauge length 50mm, travel 25mm.

6. High precision photoelectric encoder 1 set

Measuring the displacement

7. High pressure hydraulic pack 1 set

Hydraulic pack is for loading and clamping specimen hydraulically.

8. Hand control box

It can control up-and-down of crosshead and clamp the specimen hydraulically.

9. Computer system (with LCD Monitor) with English version software

Printer: HP Color DeskJet

Software (For details, Please see Annex-1)

Windows 7 operating system English, compatible test software give standards, specification and test date

under database management, the software can display tensile strength, upper and lower yield load,

modulus of elasticity, proof strength, elongation after fracture, Max. load. Other parameters can be

measured and calculated automatically by software which can display test curves of Load–deformation,

Load–time, Load-Displacement, Stress-Strain, Deformation-Time, Displacement-Time, Load-strain, etc

Test report can be edited as customer’s request.

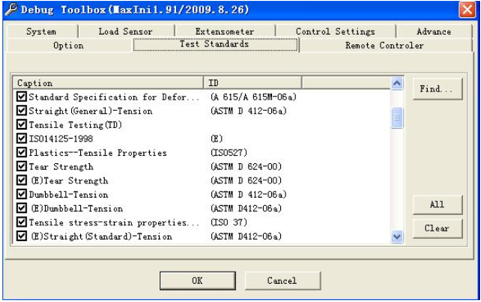

ANNEX-1: Software Introduction:

Software:

Easy to control and friendly interface

Windows based interface, easy and fast to reach different functions, suitable for most of operators using

habits.

Full digital display and computer control

Adopt special testing machine Controller, Fast response and reliable to parameter gathering. Realize the

digital adjustment and zeroing of LOAD, DEFORM and DISPLACEMENT as well as PID parameter

adjusting.

Manual or Program control of test process

The Software provides multi functional control mode: Load (Stress) Control; Displacement (Stroke)

Control, Strain (Deformation) Control. Load keeping, Displacement Keeping, Customized programming

Control, etc

In stoke control mode, operator can define customized test speed to conform to different test standard.

Preset limit position and return position will secure the safety and return the crosshead automatically after

test finished. In program control mode, the testing machine is controlled by conditional programs, operator can input each condition to regulate test process, and software can realize constant parameter control through this function.

Multilevel Authorization Access

The software regulated different access level to protect machine calibration parameters. Reliable to

secure the information safety and easy for software maintenance

Perfection of diagramming functions

Realize the testing diagram online display and reproduction.

Zoom in or out the test diagram at any place with any rate.

Auto suit the diagram according to display resolution.

Coordinates point tracing to check the test results in each point.

Test report creation as Excel, Word and Template

The software provide different way to create test report

Single material test report

Batch material test report

Customized test report

Coordinates point test report

Test Curves:

Load-time

Extension-Time

Load-Extension

Load-Displacement

Stress-Strain

Etc

Main Interface

Over 130 ASTM, ISO, DIN, etc standard is embed

One machine with 8 pcs of extensometers

One machine with 4 pcs of Load cells

Excel, word and template test report, and the report can be edited customized.