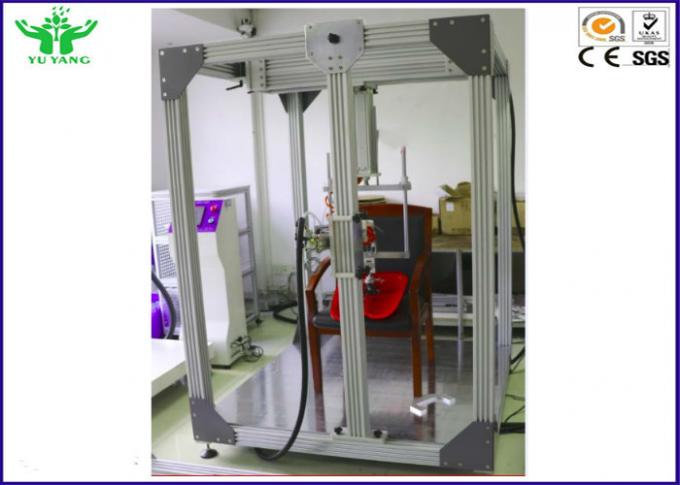

PLC Furniture Testing Maching Office Chair Seat and Back Durability Tester EN 1728

Description:

Office Chair Seat Back durability tester is used for testing the strength and durability of office chair. Made of Aluminum material frame, PLC control, easy operation; high precision force sensor for the load application.

Seat and chair back durability combined tester.

Test Items:

Seat and back Static load test: test consisting of heavy loads being applied a few times to ensure that furniture has sufficient strength under the highest levels of loading that might reasonably be expected to occur.

Seat and back Fatigue test:Test simulating the repeated application of loads or movement of components occurring during long-term functional use.

This test apparatus do the durability test to chair seat and backrest by simulating the loading application to the chair as daily use.First use the seat loading pad to apply the certain loading to the seat surface, then the back loading pad to the backrest, then loading unload to finish one cycle of test, repeat the loading movement some times and certain cycles according to different test requirement, to determine the durability performance of chairs.

Loading 600N on the seat surface,and then load 192N on the chair back

Repeated motion 200000 times in frequency of no more than 40times/min.

Office Chair Back durability tester come with aluminum frame,elegant appearance.

Pneumatic drive to load,easy to clean.

Relevant parameters:

Loading Sensor: 2500N (2nos) and 1000N (2nos) (or specified by customer)

Load force solution: 1/10000

System test force accuracy: ±1%(static) ; ±5%(dynamic)

Test speed:10~30 cycles per minute (adjustable)

Loading cycle:0~999999 adjustable

Control method:microcomputer automatism servo control

Loading method: pneumatic linear actuator

Loading power: motor

Specimen test station: 1

Test independence: independent control by each work station

Setting: computer software setting

Data storage: RAM and U disc

Test report: make the report on computer as request

Loading force adjustment:Air pressure adjustment

Motion control:PLC control

Backrest loading height: manual adjustment

Size:140x140x200cm

Air source:6kgf/cm^2 or above(supplied by customer themselves)

Power:1¡ÓAC 220V 50Hz 5A,3KW

Accessories: Seat loading pad 1 set; Back loading pad 1set; Stationary fixture 1 set.

Standards: BS EN 581-2 B.2.1.1 and B.2.1.2, EN 1728; BIFMA X5.1,QB/T2280 /GB 10357.3; and BS EN 1335.

|

Item

|

YYJ-001 |

|

System test force accuracy: |

±1%(static) ; ±5%(dynamic) |

|

Load force solution |

1/10000 |

|

The range of the seat surface height |

30 ~ 50 cm |

|

Loading times |

0 ~ 999999 times can be set |

|

Strength adjust |

Air pressure adjustment |

|

Motor control |

PLC control |

|

Beam elevation method |

Electric hoist |

|

Back of a chair loading height adjustment |

Manual adjust |

|

dimension |

140x140x200cm |

|

Air source |

6bar/0.6Mpa or more |

|

Power Supply |

AC 220V 50Hz 5A |

|

Data storage: |

RAM and U disc |

Motion control: