EN13823 Building Products Single Burning Item Flammability Testing Equipment

Description:

Method of test for determining the reaction to fire performance of building materials and products excluding flooring,and excluding products which are indicated in the EC Decision 2000/147/EC.

Standard:

EN 13823 Reaction to fire tests for building products ¨D Building products excluding floorings exposed to the thermal attack by a single burning item

GB/T 20284 Single burning item test for building materials and products

Operating Conditions:

1. Power supply: AC 220V 50HZ;

2. Power: 8.5KW;

3. Ambient temperature: 5~35 ¡æ;

4. Relative humidity:20%~80%;

5. Atmospheric pressure:0~250KPa.

Specifications:

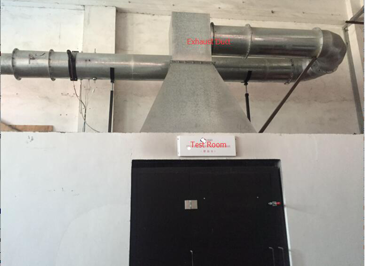

The test apparatus contains test room,control room,trolley,exhaust duct,data collection analysis device,gas supply control device.

1. Test room: L3000*W3000*H2400(MM),at the top of room connecting hood with sampling pipe and exhaust ducting,there is space for natural gas in-out blew the trolley.During testing,the combustion heat release of sample and combustion production can be discharged from exhaust duct.With brick building.

2. Ignition source,placed on trolley vertical rectangular box in the corner of the 31 kw propane sandbox burners(two equal sides 0f 250mm,height 80mm);

3. Exhaust pipe is provided with general measurement section for placing sensors and sampling tubes;

4. Exhaust speed: 0.50 m3 /S~0.65 m 3/ S;

5. Test room ambient temperature measurement:K-type sheathed thermocouples with diameter 2mm,ambient pressure test accuracy: ± 200Pa;

6. Flue temperature measurement:K-type sheathed thermocouples with diameter 0.5mm;

7. Temperature measurement accuracy: 0.5 ¡æ;

8. Flue high-precision pressure sensor accuracy: ± 2Pa;

9. Time recording system accuracy: 0.1S;

10. Test time: 1 to 30 minutes can be set;

11. Smoke density measurement system to measure the density of the smoke during testing;

12. Gas analyzer, and the key components are imported.

13. Embedded computers and 8.4-inch LCD display with TCP / IP and RS-232 communication interfaces can be choice;

14. Oxygen measurement:

1 ) Measuring range: 0-25%

2) Signal output: 4-20mA;

3 ) Response time T90: ≤2S;

4 ) Ambient temperature: 0-45 ¡æ;

5 ) Relative humidity: <90% (non-condensing);

6 ) Linearity: <± 0.1% O2;

7 ) Zero drift: 0.05% O2 per week;

8 ) Repeatability: <± 0.02% O2;

15. Carbon dioxide(CO2) measurement:

1) Measuring range:0-10%;

2) Repeatability: <± 1% internal structure of the control cabinet;

3) Zero drift: ≤2% / week;

4) Span drift: ≤2% / week;

5) Linearity deviation: <± 1%;

6) Response time: T90≤2 seconds;

16. Record data acquisition system can collect oxygen concentration, carbon monoxide concentration, temperature, smoke density, heat release rate, mass loss rate, etc., can be stored.

Test principle:

1. A sample consisting of two vertically angled vertical wings is exposed to the flame produced by the main burner at the bottom of the right angle, the flame is produced by the combustion of propane gas, the propane gas passes through the sandbox burner and produces (30.7 ± 2.0) kW of heat output.

2. The combustion performance of the sample was evaluated by the entire test procedure of 20 min. Performance parameters include: heat release, smoke production, flame propagation and burning dripping and particulate matter.

3. Prior to igniting the main burner, the heat output and smoke generation of the burner itself should be measured for a short time using the auxiliary burner remote from the sample.

4. Some parameters can be measured automatically, while others can be obtained by visual inspection. The smoke pipe is equipped with a sensor for measuring the temperature, light attenuation, the mole fractions of O2 and CO2, and the airflow in the pipeline. These values are automatically recorded and used to calculate the volumetric flow rate, heat release rate (HRR) and smoke rate (SPR).

The transverse propagation and burning of the flame and the particulate matter can be measured using a visual method.

SBI trolley

SBI trolley  Control Box

Control Box

Exhaust Duct

Exhaust Duct  Hood

Hood